Made in Iowa: Low Carbon 3D Printed Concrete from Local Waste

Concrete is the most widely used construction material in the world and is responsible for 8% of annual green house gas emissions. In 2017, the global market for ready-mix concrete was valued at $394.44 billion. This market is expected to double by 2024 and the 3D printing market is projected to grow exponentially by 2030.

Concrete is the most widely used construction material in the world and is responsible for 8% of annual green house gas emissions. In 2017, the global market for ready-mix concrete was valued at $394.44 billion. This market is expected to double by 2024 and the 3D printing market is projected to grow exponentially by 2030.

In this context, there is urgent demand for innovations that can reduce the costs and environmental impacts associated with concrete design and construction.

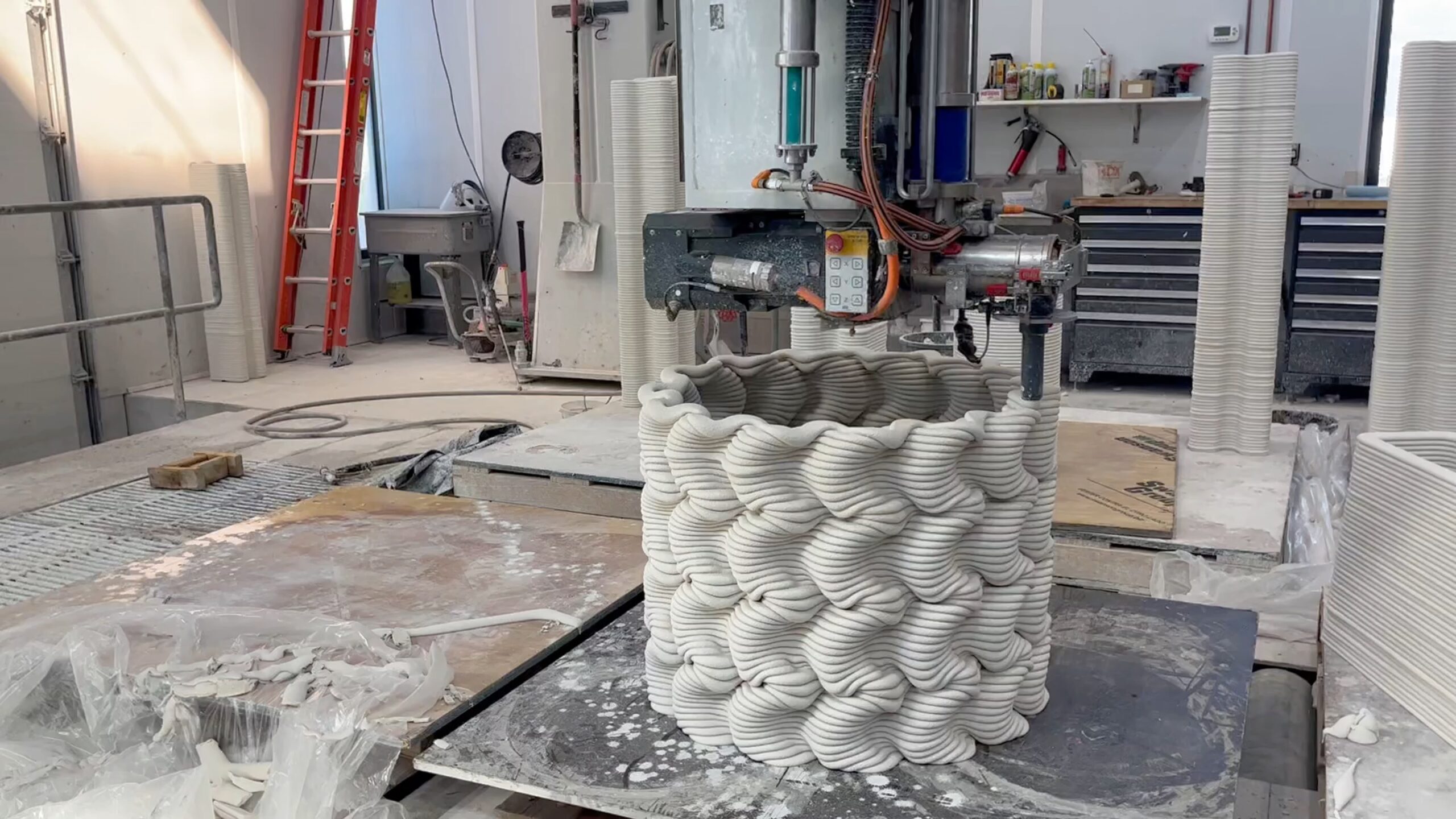

- Students in this studio will research, design, and 3D print alternatives to traditional concrete using a Potterbot for small tests and a Scara construction printer for full scale mock-ups.

- Students will engage with ongoing research to develop low carbon 3D printed concrete made from decommissioned wind turbines and corn stover ash.

- The final project will be a public library addition and courtyard designed to mitigate flooding through 3D printing.

| Course credits: | 6 |

| Meeting days and times: | Monday / Wednesday / Friday, 1:10 p.m. to 5:20 p.m. |

| Variable course fee: | $100 – $600 |

| Field trips: | TBD |

| Maximum enrollment: | 16 |

| Enrollment open to: | All seniors (4th and 5th years) in all College of Design majors |

- Social Entrepreneurship

- Intrapreneurship

- Civic Innovation

- Affordable and clean energy

- Industry, innovation, and infrastructure

- Sustainable cities and communities

- Responsible consumption and production

Learn more about the United Nations Sustainable Development Goals